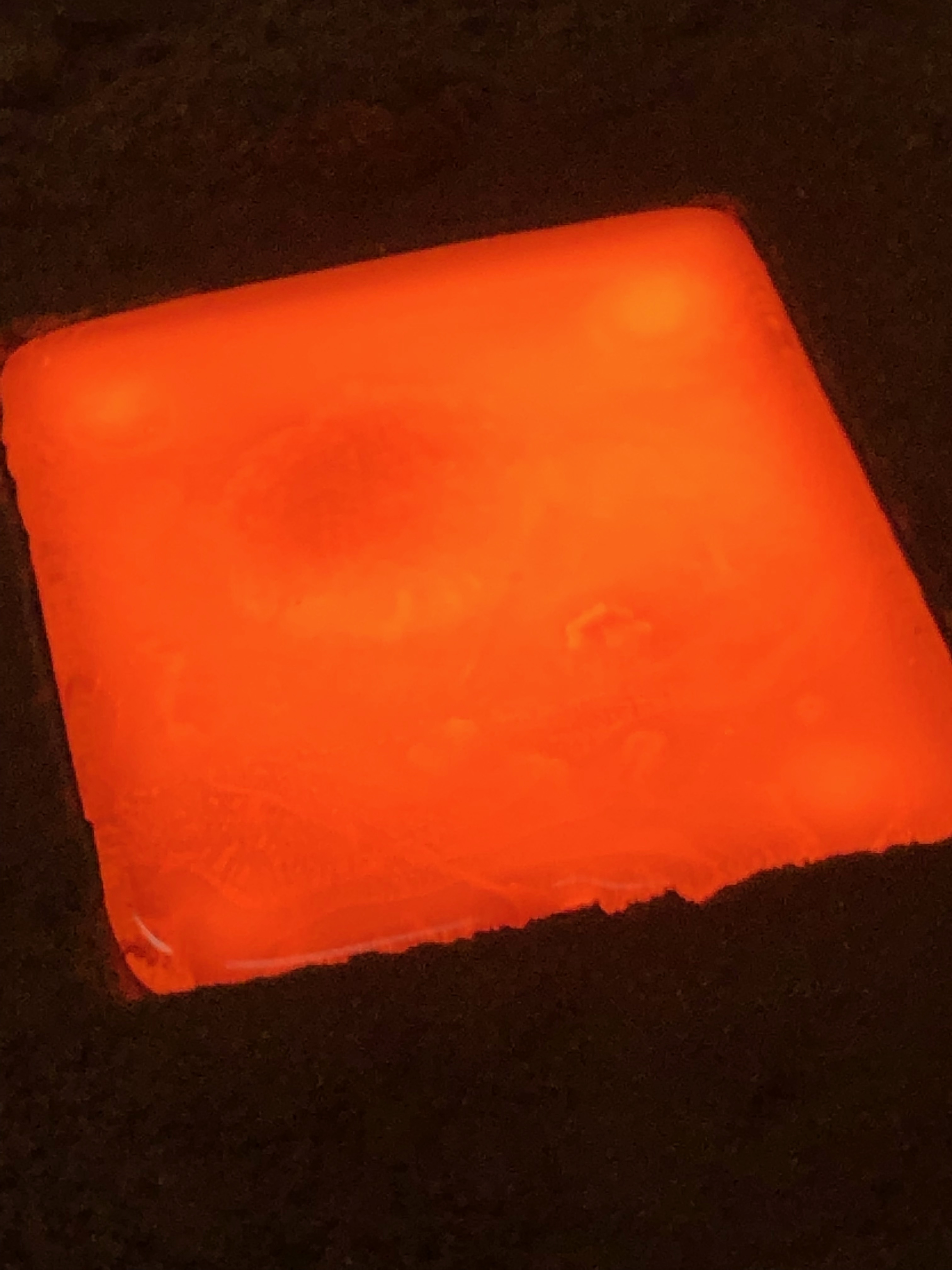

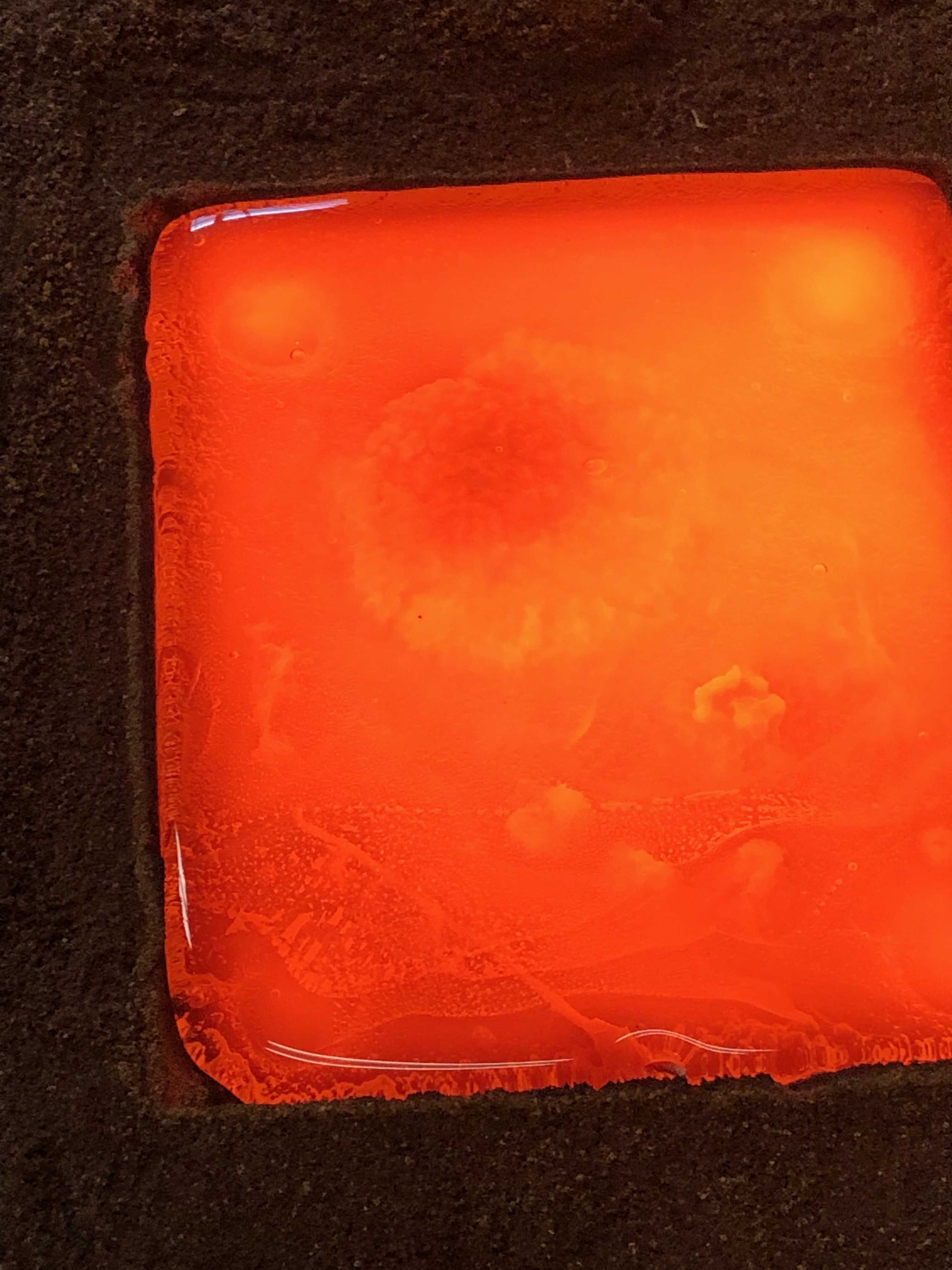

Not the sad blues! I charged the furnace with every piece of glass I could find that didn’t work out or scraps from the pipes of any colour including white, black, green, pink… any colour I have ever worked with in the hot shop I saved in buckets just for this week.

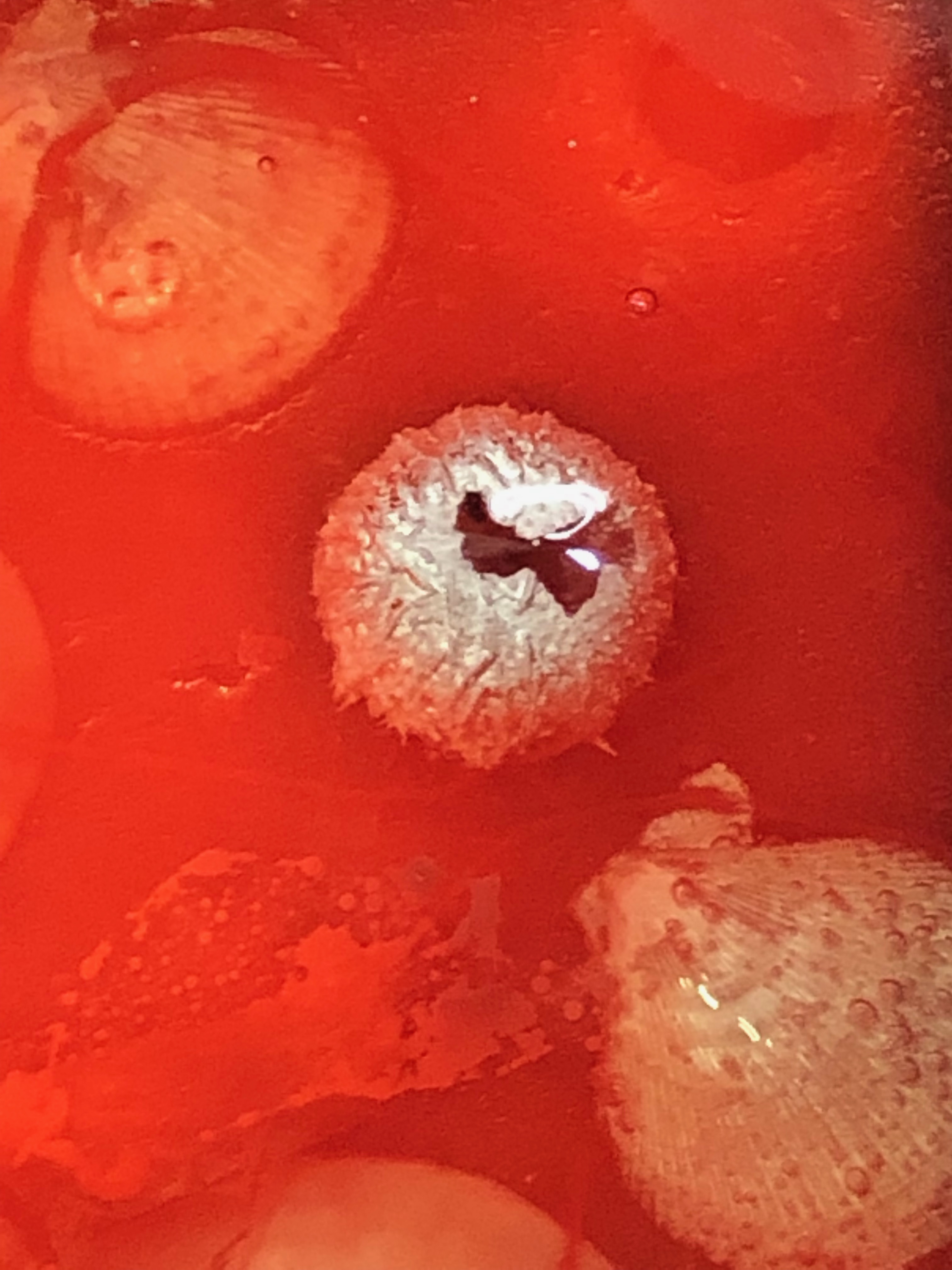

I ended up with 8 big buckets of glass that really should have gone into the garbage but to glass blowers – glass is precious. It is expensive and is coveted. As a result all the glass in the furnace is now blue. A beautiful transparent blue that makes for great castings.

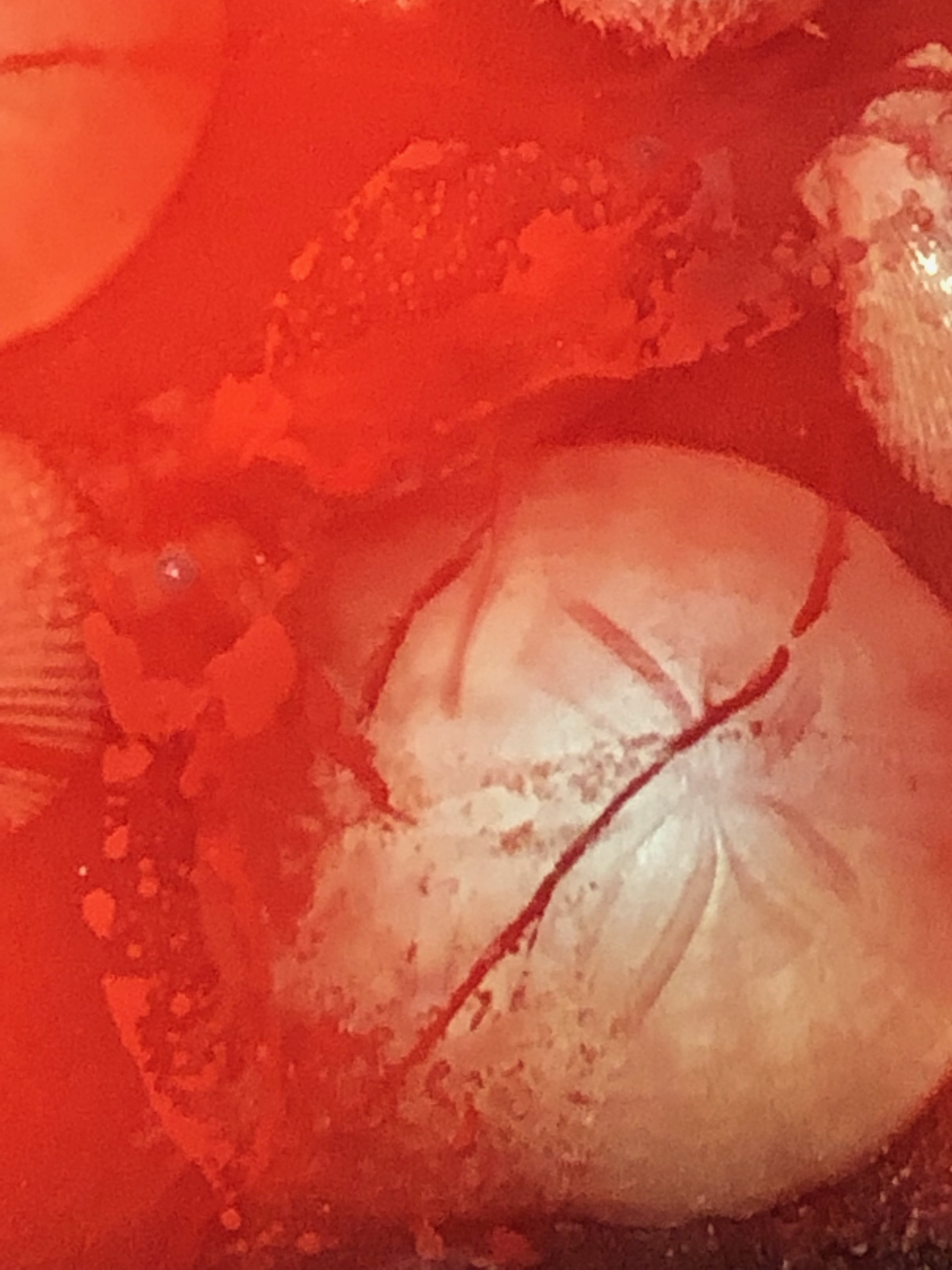

Because the castings are so thick it takes longer to come down in temperature – the wait is approximately 2 days. But oh so worth it!

Photo credits and video credits go to by brother Dakota… my family, my assistant, my rock.